File Info

| Exam | Certified in Planning and Inventory Management (Part 2) |

| Number | CPIM-Part-2 |

| File Name | APICS.CPIM-Part-2.NewDumps.2023-11-23.27q.tqb |

| Size | 308 KB |

| Posted | Nov 23, 2023 |

| Download | APICS.CPIM-Part-2.NewDumps.2023-11-23.27q.tqb |

How to open VCEX & EXAM Files?

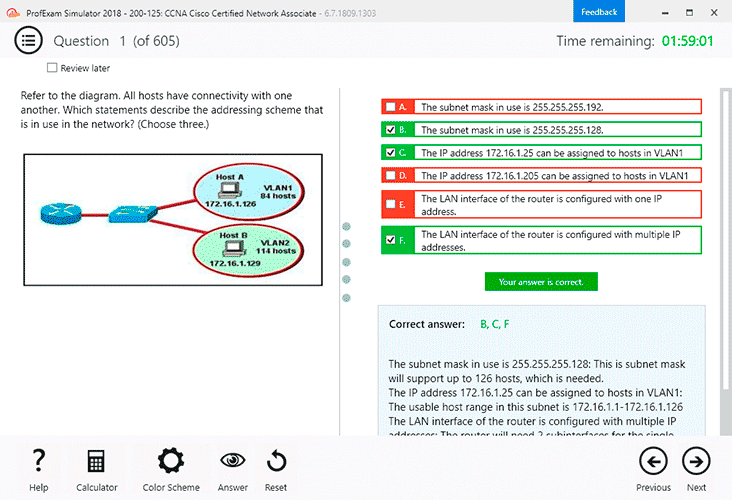

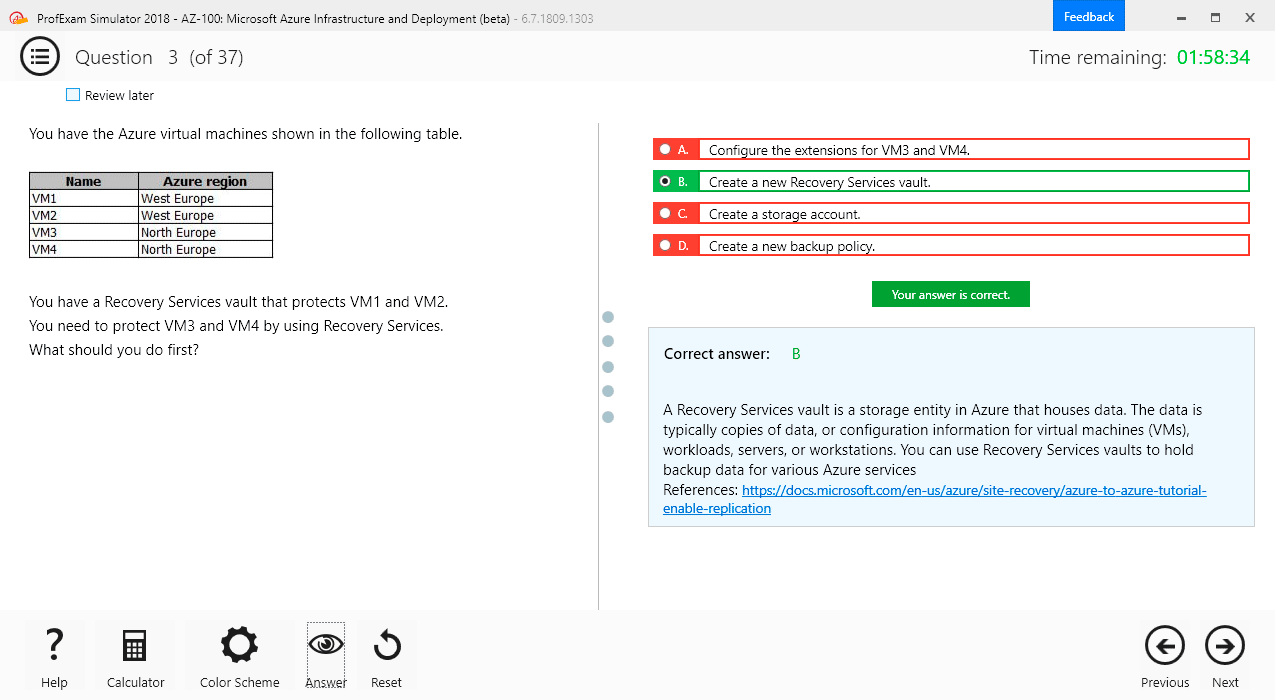

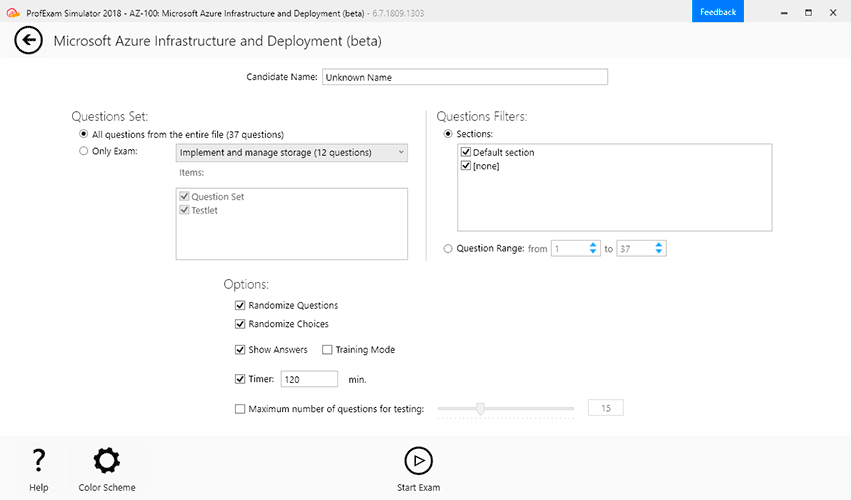

Files with VCEX & EXAM extensions can be opened by ProfExam Simulator.

Coupon: MASTEREXAM

With discount: 20%

Demo Questions

Question 1

What is the purpose of a buffer in the theory of constraints (TOC)?

- It allows for processing jobs at a lower rate than demand.

- It prevents unplanned idleness of the resource.

- It identifies the root cause of the constraint.

- It opens an opportunity to exploit the system.

Correct answer: B

Explanation:

A buffer in the theory of constraints (TOC) is a level of inventory that is placed before the governing constraint or the bottleneck to prevent it from being starved or idle. Buffers are used to immunize the system's performance from variability in demand or production. Buffers are part of the drum buffer rope method of scheduling and managing operations that have constraints. The purpose of a buffer in TOC is to prevent unplanned idleness of the resource, which is the most important factor that determines the throughput of the system. Throughput is the rate at which the system generates money through sales. If the resource is idle, then the system loses potential throughput and profit. Therefore, buffers are designed to ensure that there is always enough work available for the resource to process, regardless of any fluctuations or disruptions in the upstream or downstream processes. A buffer in the theory of constraints (TOC) is a level of inventory that is placed before the governing constraint or the bottleneck to prevent it from being starved or idle. Buffers are used to immunize the system's performance from variability in demand or production. Buffers are part of the drum buffer rope method of scheduling and managing operations that have constraints. The purpose of a buffer in TOC is to prevent unplanned idleness of the resource, which is the most important factor that determines the throughput of the system. Throughput is the rate at which the system generates money through sales. If the resource is idle, then the system loses potential throughput and profit. Therefore, buffers are designed to ensure that there is always enough work available for the resource to process, regardless of any fluctuations or disruptions in the upstream or downstream processes.

Question 2

Which of the following tools is used for monitoring a capacity plan?

- Demonstrated capacity

- Resource planning

- Input/output control (I/O)

- Dispatch report &

Correct answer: C

Explanation:

Input/output control (I/O) is a type of tool that is used for monitoring a capacity plan. A capacity plan is a statement of the resources needed to meet the production plan over a medium-term horizon. A capacity plan can be stated in different units of measure depending on the type of manufacturing environment, such as hours, units, tons, or dollars. Input/output control (I/O) is a method of measuring and comparing the actual input and output of a work center or a production line against the planned input and output. Input is the amount of work that is released to the work center or the production line, and output is the amount of work that is completed by the work center or the production line. Input/output control (I/O) helps to monitor the performance and efficiency of the work center or the production line, and to identify any deviations or problems that may affect the capacity plan. Input/output control (I/O) also helps to adjust the input or output levels as necessary to maintain the balance between demand and supply, and to achieve the desired throughput. Input/output control (I/O) is a type of tool that is used for monitoring a capacity plan. A capacity plan is a statement of the resources needed to meet the production plan over a medium-term horizon. A capacity plan can be stated in different units of measure depending on the type of manufacturing environment, such as hours, units, tons, or dollars. Input/output control (I/O) is a method of measuring and comparing the actual input and output of a work center or a production line against the planned input and output. Input is the amount of work that is released to the work center or the production line, and output is the amount of work that is completed by the work center or the production line. Input/output control (I/O) helps to monitor the performance and efficiency of the work center or the production line, and to identify any deviations or problems that may affect the capacity plan. Input/output control (I/O) also helps to adjust the input or output levels as necessary to maintain the balance between demand and supply, and to achieve the desired throughput.

Question 3

The primary consideration in maintenance, repair, and operating (MRO) supply systems typically is:

- order quantity.

- stockout costs.

- carrying costs.

- shelf life.

Correct answer: B

Explanation:

Maintenance, repair, and operating (MRO) supply systems are systems that manage the inventory and procurement of the items that are used to support the production process, but are not part of the final product. MRO items include spare parts, tools, lubricants, cleaning supplies, safety equipment, and office supplies. The primary consideration in MRO supply systems typically is stockout costs. Stockout costs are the costs associated with the inability to meet the demand for an item due to insufficient inventory. Stockout costs can include lost sales, customer dissatisfaction, production downtime, emergency orders, and reputation damage. Stockout costs can be very high for MRO items, especially if they are critical for the operation and maintenance of the production equipment. Therefore, MRO supply systems should aim to minimize the risk of stockouts by ensuring adequate availability and accessibility of MRO items. Maintenance, repair, and operating (MRO) supply systems are systems that manage the inventory and procurement of the items that are used to support the production process, but are not part of the final product. MRO items include spare parts, tools, lubricants, cleaning supplies, safety equipment, and office supplies. The primary consideration in MRO supply systems typically is stockout costs. Stockout costs are the costs associated with the inability to meet the demand for an item due to insufficient inventory. Stockout costs can include lost sales, customer dissatisfaction, production downtime, emergency orders, and reputation damage. Stockout costs can be very high for MRO items, especially if they are critical for the operation and maintenance of the production equipment. Therefore, MRO supply systems should aim to minimize the risk of stockouts by ensuring adequate availability and accessibility of MRO items.